CIPP PIPE LINING EQUIPMENT & SUPPLIES

The trenchless CIPP (Cured-In-Place Pipe) lining rehabilitation process is versatile, primarily addressing sewer and storm drain repairs & maintenance. CIPP pipe lining effectively repairs cracked or broken pipes, eliminates invasive roots, bridges gaps in missing pipe sections, and seals faulty joints. Explore our comprehensive range of equipment, materials, training, and technical support to either kickstart your CIPP lining services or tackle complex projects as a seasoned pipe lining contractor.

CIPP PIPE LINING EQUIPMENT & SUPPLIES

The trenchless CIPP (Cured-In-Place Pipe) lining rehabilitation process is versatile, primarily addressing sewer and storm drain repairs & maintenance. CIPP pipe lining effectively repairs cracked or broken pipes, eliminates invasive roots, bridges gaps in missing pipe sections, and seals faulty joints. Explore our comprehensive range of equipment, materials, training, and technical support to either kickstart your CIPP lining services or tackle complex projects as a seasoned pipe lining contractor.

CIPP PIPE LINING EQUIPMENT & SUPPLIES

The trenchless CIPP (Cured-In-Place Pipe) lining rehabilitation process is versatile, primarily addressing sewer and storm drain repairs & maintenance. CIPP pipe lining effectively repairs cracked or broken pipes, eliminates invasive roots, bridges gaps in missing pipe sections, and seals faulty joints. Explore our comprehensive range of equipment, materials, training, and technical support to either kickstart your CIPP lining services or tackle complex projects as a seasoned pipe lining contractor.

Pipe Lining Materials

Our pipe lining materials are renowned for their quality and reliability, setting the standard in the trenchless pipe repair industry. We offer an extensive range of consumables, including premium liners and advanced resins, ensuring optimal performance and durability for every project. Whether you’re addressing minor repairs or tackling large-scale rehabilitations, our materials provide the best solutions for all your pipe lining needs.

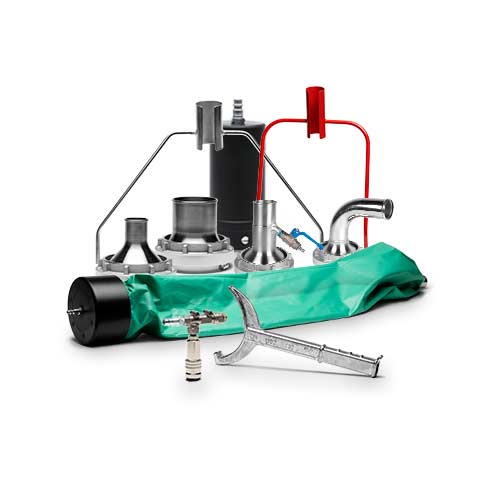

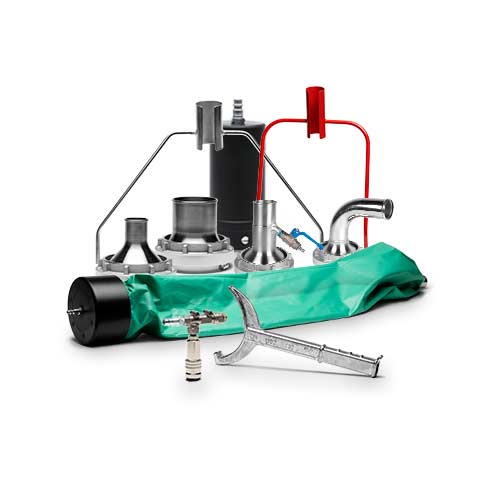

Pipe Lining Equipment

Our comprehensive range of pipe lining equipment includes specialized tools for inversion lining, such as durable drums and essential attachments. We provide all necessary accessories to streamline the installation process, ensuring efficient and effective liner placement in drainage systems. Equip yourself with our high-quality tools for a seamless and reliable pipe rehabilitation experience.

LINER MATERIAL

Our range of pipe lining liners includes both fixed size options and highly flexible liners that adapt to dimensional changes and multiple 90° bends with minimal wrinkling. These liners provide long-lasting performance and seamless pipe rehabilitation across various sizes and conditions.

RESIN SUPPLIES

Our pipe lining resins, designed to complement our liners, deliver outstanding versatility with many curing options from ultra-fast to slow for either ambient, hot-cure, or UV/LED applications. Each resin is formulated for precise working times and temperatures, ensuring optimal performance, durability, and reliability.

PIPE LINING INVERSION DRUMS

Lightweight aluminum inversion drums, expertly designed for efficient liner installation using compressed air to invert and cure the liner under pressure. Available in various sizes, large capacity or compact for navigating tight spaces. Suitable for air, steam, and water inversion applications.

LINING TOOLS & ACCESSORIES

From specialized curing caps and inversion heads to air regulators, Picote’s pressure guards, vacuum pumps, and wet-out stations, we offer a comprehensive range of tools and accessories to help facilitating your pipe lining service, ensuring precise installation and efficient operation.

Pipe Lining Materials

Our pipe lining materials are renowned for their quality and reliability, setting the standard in the trenchless pipe repair industry. We offer an extensive range of consumables, including premium liners and advanced resins, ensuring optimal performance and durability for every project. Whether you’re addressing minor repairs or tackling large-scale rehabilitations, our materials provide the best solutions for all your pipe lining needs.

LINER MATERIAL

Our range of pipe lining liners includes both fixed size options and highly flexible liners that adapt to dimensional changes and multiple 90° bends with minimal wrinkling. These liners provide long-lasting performance and seamless pipe rehabilitation across various sizes and conditions.

RESIN SUPPLIES

Our pipe lining resins, designed to complement our liners, deliver outstanding versatility with many curing options from ultra-fast to slow for either ambient, hot-cure, or UV/LED applications. Each resin is formulated for precise working times and temperatures, ensuring optimal performance, durability, and reliability.

Pipe Lining Equipment

Our comprehensive range of pipe lining equipment includes specialized tools for inversion lining, such as durable drums and essential attachments. We provide all necessary accessories to streamline the installation process, ensuring efficient and effective liner placement in drainage systems. Equip yourself with our high-quality tools for a seamless and reliable pipe rehabilitation experience.

PIPE LINING INVERSION DRUMS

Lightweight aluminum inversion drums, expertly designed for efficient liner installation using compressed air to invert and cure the liner under pressure. Available in various sizes, large capacity or compact for navigating tight spaces. Suitable for air, steam, and water inversion applications.

LINING TOOLS & ACCESSORIES

From specialized curing caps and inversion heads to air regulators, Picote’s pressure guards, vacuum pumps, and wet-out stations, we offer a comprehensive range of tools and accessories to help facilitating your pipe lining service, ensuring precise installation and efficient operation.

PICOTE LINING CANNON

The Picote Solutions Cannon is an optimal solution for installing short liners as small as DN50. Designed to fit in tight spaces where traditional inversion drums cannot, this compact and transparent device is ideal for short DN50-DN150 liners. The Picote Cannon’s innovative Fast Lock System allows for rapid transitions between liners, enabling multiple installations in quick succession. This streamlined approach enhances efficiency in CIPP lining and trenchless pipe repairs.

PICOTE LINING CANNON

The Picote Solutions Cannon is an optimal solution for installing short liners as small as DN50. Designed to fit in tight spaces where traditional inversion drums cannot, this compact and transparent device is ideal for short DN50-DN150 liners. The Picote Cannon’s innovative Fast Lock System allows for rapid transitions between liners, enabling multiple installations in quick succession. This streamlined approach enhances efficiency in CIPP lining and trenchless pipe repairs.

How Inversion Lining Technology Works

In inversion lining, the process begins with impregnating a liner with a specialized resin. To ensure precision thorough saturation, the liner is carefully rolled out with the use of a manual or mechanical roller. Next, the resin-saturated liner is loaded into an inversion drum. Using compressed air, the drum inverts the liner inside the pipe, where it adheres to the existing pipe walls. The liner is held in place as it cures, forming a new durable and seamless pipe. This method not only repairs damaged pipes but also enhances their structural integrity, offering a long-lasting and effective solution for trenchless pipe rehabilitation.

How Inversion Lining Technology Works

In inversion lining, the process begins with impregnating a liner with a specialized resin. To ensure precision thorough saturation, the liner is carefully rolled out with the use of a manual or mechanical roller. Next, the resin-saturated liner is loaded into an inversion drum. Using compressed air, the drum inverts the liner inside the pipe, where it adheres to the existing pipe walls. The liner is held in place as it cures, forming a new durable and seamless pipe. This method not only repairs damaged pipes but also enhances their structural integrity, offering a long-lasting and effective solution for trenchless pipe rehabilitation.

How Inversion Lining Technology Works

In inversion lining, the process begins with impregnating a liner with a specialized resin. To ensure precision thorough saturation, the liner is carefully rolled out with the use of a manual or mechanical roller. Next, the resin-saturated liner is loaded into an inversion drum. Using compressed air, the drum inverts the liner inside the pipe, where it adheres to the existing pipe walls. The liner is held in place as it cures, forming a new durable and seamless pipe. This method not only repairs damaged pipes but also enhances their structural integrity, offering a long-lasting and effective solution for trenchless pipe rehabilitation.

Liner Curing

Liner curing in pipe lining can be achieved through various methods, each suited to different project needs. From the simplicity of ambient curing to the speed of hot water and steam curing, these methods ensure efficient and durable pipe rehabilitation. UV/LED light curing offers rapid and precise results, while heat curing provides targeted solutions. Our advanced curing equipment is designed to support all these methods, ensuring optimal performance and reliability in your CIPP lining projects.

Liner Curing

Liner curing in pipe lining can be achieved through various methods, each suited to different project needs. From the simplicity of ambient curing to the speed of hot water and steam curing, these methods ensure efficient and durable pipe rehabilitation. UV/LED light curing offers rapid and precise results, while heat curing provides targeted solutions. Our advanced curing equipment is designed to support all these methods, ensuring optimal performance and reliability in your CIPP lining projects.

Ambient / Heat Cure

Ambient curing offers a straightforward, no-fuss option with minimal equipment, ideal for curing small diameter liners over short lengths. Picote’s innovative “Smart Heat” cable heater provides targeted and efficient heat, raising the temperature to accelerate curing when faster results are needed. This ensures flexible and reliable curing in a wide range of conditions.

UV / LED Light Cure

UV/LED curing equipment is designed for precision and speed in pipe lining. Utilizing advanced UV or LED light technology, resin-impregnated liners can be rapidly cured, ensuring a quick and efficient installation process. UV/LED systems deliver consistent and reliable results, minimizing downtime and disruption while maintaining high-quality pipe rehabilitation.

Steam / Hot Water Curing

For large projects requiring fast curing, steam and hot water methods offer optimal performance. By circulating steam or hot water through the liner, this technique significantly accelerates the curing process, making it ideal for larger diameter installations. Picote’s Midi Steamer is perfect for short or small diameter liners and branch liners (Connection Collars), making it an excellent choice for in-house pipe-lining jobs.

Our main CIPP pipe lining brands

Each machine, tool, and material in our inventory has been meticulously selected for its superior reputation in the trenchless pipe repair industry. At Green Moles, we prioritize quality and reliability, which is why every product undergoes rigorous testing by our experienced teams before being added to our collection. This ensures that our customers receive only the best equipment and materials for CIPP lining and trenchless drain repairs. Our commitment to excellence means you can trust that every item we offer has been proven effective in real-world applications, providing the highest level of performance and durability for your trenchless pipe repair needs.

Our main CIPP pipe lining brands

Each machine, tool, and material in our inventory has been meticulously selected for its superior reputation in the trenchless pipe repair industry. At Green Moles, we prioritize quality and reliability, which is why every product undergoes rigorous testing by our experienced teams before being added to our collection. This ensures that our customers receive only the best equipment and materials for CIPP lining and trenchless drain repairs. Our commitment to excellence means you can trust that every item we offer has been proven effective in real-world applications, providing the highest level of performance and durability for your trenchless pipe repair needs.

CIPP PIPE LINING TRAINING

At our state-of-the-art training center in Cyprus, we offer comprehensive training on CIPP lining methodologies, materials, and equipment. Delivered by our highly skilled technicians with extensive hands-on experience, our training programs are can be tailored to equip you with the practical knowledge and technical expertise you need for successful trenchless pipe repairs.

Whether you’re new to the industry or looking to enhance your skills, our courses cover everything from fundamental techniques to advanced applications, ensuring you’re fully prepared to handle any CIPP lining project. Join us in Cyprus to learn from the experts and master the latest in trenchless drain repair technologies.

ON-SITE SUPPORT

Our team can provide technical support and on-site assistance to ensure the success of your CIPP pipe lining projects. Our expert team can guide you through every step, from selecting the right materials and equipment, to troubleshooting on-site challenges.

With years of hands-on experience in trenchless pipe repairs, our engineers offer personalized advice and real-time solutions, helping you overcome any obstacles you may encounter.

Whether you need remote technical support or in-person assistance at your job site, Green Moles can provide the expertise and support necessary to keep your operations running smoothly and efficiently.

CIPP PIPE LINING TRAINING

At our state-of-the-art training center in Cyprus, we offer comprehensive training on CIPP lining methodologies, materials, and equipment. Delivered by our highly skilled technicians with extensive hands-on experience, our training programs are can be tailored to equip you with the practical knowledge and technical expertise you need for successful trenchless pipe repairs.

Whether you’re new to the industry or looking to enhance your skills, our courses cover everything from fundamental techniques to advanced applications, ensuring you’re fully prepared to handle any CIPP lining project. Join us in Cyprus to learn from the experts and master the latest in trenchless drain repair technologies.

ON-SITE SUPPORT

Our team can provide technical support and on-site assistance to ensure the success of your CIPP pipe lining projects. Our expert team can guide you through every step, from selecting the right materials and equipment, to troubleshooting on-site challenges.

With years of hands-on experience in trenchless pipe repairs, our engineers offer personalized advice and real-time solutions, helping you overcome any obstacles you may encounter.

Whether you need remote technical support or in-person assistance at your job site, Green Moles can provide the expertise and support necessary to keep your operations running smoothly and efficiently.

GET MORE PRODUCT INFORMATION

Request guidance or more product information by submitting this contact form.